Welcome to the world of 3D printing, a game-changer in the realm of creativity and design. With the power of additive manufacturing, designers can now bring their digital creations to life, layer by layer, unlocking a world of possibilities and pushing the limits of imagination. This cutting-edge technology is revolutionizing the design process and transforming industries by offering precision, rapid prototyping, customization, and waste reduction. Let’s dive into the exciting world of 3D printing and explore how it is shaping the future of creativity.

Key Takeaways:

- 3D printing allows designers to create objects layer by layer directly from a digital model.

- Precision and accuracy are the core strengths of 3D printing.

- Rapid prototyping accelerates the design-to-prototype timeline.

- Customization is a key advantage of 3D printing, allowing for personalized designs.

- 3D printing reduces waste and aligns with eco-friendly practices.

The Growing Influence of 3D Printing in Industrial Production

As 3D printing technology continues to advance and evolve, its impact on industrial production is becoming increasingly significant. Major companies like GE, Lockheed Martin, and BMW are embracing 3D printing as a scalable solution for their manufacturing processes.

One of the key advantages of 3D printing in industrial production is the expanding range of printable materials. While basic plastics were initially the primary focus, this technology has progressed to include metals, ceramics, and even stem cells. This broadening selection of materials enables manufacturers to create diverse and complex products with ease.

Cost savings are another driving factor behind the adoption of 3D printing in industrial production. With 3D printing, fewer assembly steps are required, reducing labor costs and minimizing the need for specialized tooling. Additionally, this technology offers greater flexibility, allowing for rapid prototyping and efficient iteration of product designs.

The strategic implications of 3D printing cannot be ignored. Managers and decision-makers must consider how this technology will shape their offerings, operations, and commercial ecosystems. The ability to 3D print on demand opens up new possibilities, such as decentralized production and localized supply chains. Understanding and harnessing these implications will be crucial in staying competitive in the rapidly evolving manufacturing landscape.

Furthermore, the commoditization of 3D printing in industrial production will have substantial consequences. As this technology becomes more accessible and widespread, it has the potential to disrupt traditional supply chains and distribution models. Platform owners in the 3D printing industry, who can facilitate connections and collaborations within the digital ecosystem, will wield significant power as production transitions from centralized to decentralized.

In this emerging digital ecosystem, organizations will need to adapt and forge strategic partnerships to navigate the complex landscape and take advantage of the opportunities it presents. The shift toward additive manufacturing will not only revolutionize the production process but also impact product design possibilities and overall business models.

With 3D printing’s transformative potential in industrial production, it is essential for businesses to stay informed and proactive in embracing this technology. The ability to leverage printable materials, achieve cost savings, comprehend strategic implications, and participate in commercial ecosystems will be the keys to success in this new era of manufacturing.

3D Printing as a Medium for Artistic Expression

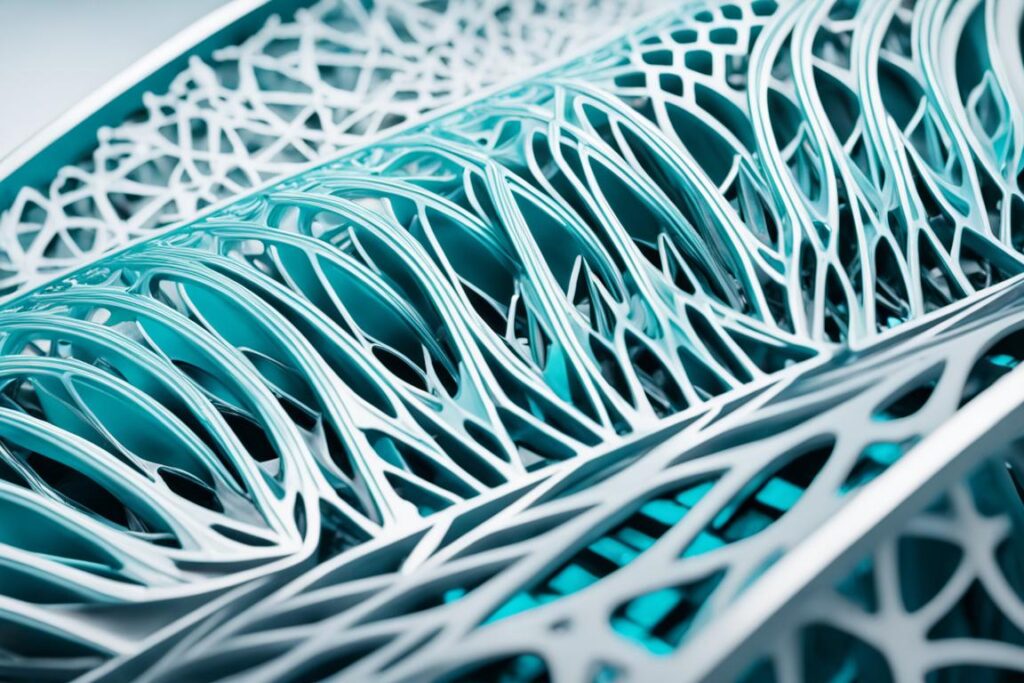

3D printing has sparked a creative revolution, offering new possibilities for artists across various disciplines. From sculpture and fashion to installation art, this innovative technology is reshaping the landscape of artistic expression.

One of the key advantages of 3D printing for artists is the unprecedented design freedom it provides. With 3D printing, artists can bring their wildest ideas to life, pushing the boundaries of what was previously thought possible. The ability to create customized pieces opens up a world of creative exploration, allowing artists to make their visions tangible.

In the realm of fashion, designers are embracing 3D printing to craft intricately detailed garments and accessories. The technology enables them to produce truly unique and avant-garde designs that were once unattainable through traditional methods. From elegant couture to futuristic streetwear, 3D printing is revolutionizing the fashion industry.

Furthermore, artists are harnessing the power of 3D printing to create awe-inspiring sculptures and captivating installation art. The technology enables the production of large-scale artworks with intricate and complex designs, pushing the boundaries of what is physically achievable. Additionally, 3D scanning and digital workflows are revolutionizing the restoration of historical artworks, allowing for accurate replication and preservation.

What sets 3D printing apart is the diverse range of materials it can utilize. From plastics and metals to ceramics and even organic materials like stem cells, artists have a vast palette to experiment with. This versatility gives rise to innovative and interdisciplinary projects that blend art, science, and technology, creating immersive experiences that captivate audiences.

In conclusion, 3D printing is opening up a world of possibilities for artists to unleash their creativity. With design freedom, customized pieces, and a wealth of materials at their disposal, artists can bring their visions to life like never before. Whether it’s fashion, sculpture, or installation art, 3D printing is revolutionizing artistic expression across diverse mediums.

You can get 3D Printing service from 3d directory, hubs, makelab